X 射线分析

使用 X 射线荧光和 X 射线衍射仪的 X 射线分析技术

在许多生产或研发环境中,X 射线可用于表征材料和样品。X 射线波长范围(从 0.01 到 10nm)使其特别适合用于在原子水平上分析结构和元素。

可通过以下几种主要技术使用 X 射线来帮助表征样品。

29 November 2018 | English

XRD 和 XRF 都使用 X 射线源和 X 射线探测器,它们是具有多种相似性的互补技术,但这两种技术提供的信息却截然不同。

XRD 提供有关样品中存在的结晶相的信息,并且可以区分化合物 - 例如不同的氧化态 (Fe2O3/Fe3O4) 或不同的多晶型(赤铁矿与磁赤铁矿,两者都是氧化铁 Fe2O3)。

XRF 提供有关样品化学(元素)组成的信息,即存在哪些元素(Fe、O)以及含量。XRF 的主要优点之一是它可以检测低至 100 ppb(十亿分之一)的化学元素的含量。与替代技术相比,XRF 样品制备也非常快速、简单和安全。

Malvern Panalytical 是一家全球领先的 X 射线分析设备提供商,拥有数十年的丰富经验。

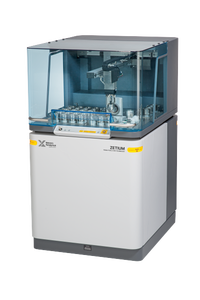

我们提供范围广泛的解决方案,从易于使用的台式系统到适用于 XRF 和 XRD 的全功率、综合落地式系统。

这些技术是互补的,在许多生产控制环境中,会使用两种类型的设备,以确保最佳质量保证。

紧凑型台式 X 射线衍射仪

智能X射线衍射仪

高端落地式 WDXRF 光谱仪

台式及在线 EDXRF 光谱仪

高通量同步 WDXRF 光谱仪

直接洞悉您的生产过程