Using laser diffraction to measure particle size and distribution of metal powders

文章

用于粉末注塑成型的材料表征解决方案

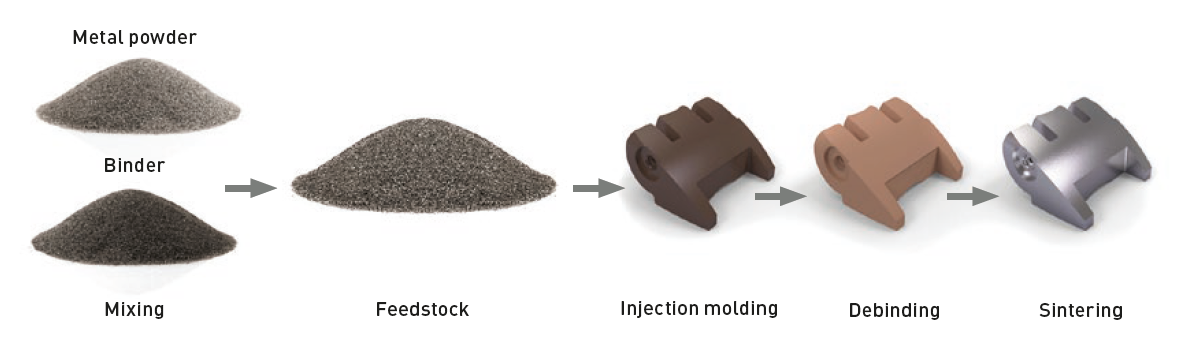

粉末注塑成型 (PIM) 和金属注塑成型 (MIM) 都属于粉末冶金工艺,它们是通过将金属或陶瓷细粉末与粘结剂材料混合来制备原料。 这些原料随后会通过注塑工艺加工成“成型坯”。 注塑后,产品还要经过脱脂和最后的烧结工序,以将粉末熔融成致密的产品。

为了生产出质量一致的原料、成型坯以及最终组件,粉末注塑成型和金属注塑成型的制造商需要仔细表征所用金属或陶瓷粉末颗粒的性能。 为了满足这一需求,Malvern Panalytical 推出多种适用于粉末注塑成型和金属注塑成型应用的材料表征解决方案。

在粉末注塑成型 (PIM) 和金属注塑成型 (MIM) 应用领域,原料的流变性能非常重要,因为它们会影响熔融原料的均匀性、经过熔模流入模腔的易流动性以及成型坯在冷却时的机械性能。 这些流变性能受多种因素影响,包括粘结剂的分子量和分子结构、固体负荷、粒度和粒形、温度以及流速。 大多数具有合适粉末特性(包括粒度和形状)的金属和陶瓷均可用于粉末注塑成型。

因此,要使用多样的材料生产出高质量的原料、成型坯和最终组件,制造商必须仔细地表征这些特性。 特别是,因为需要高堆积密度,所以具有正确粒度分布的球形颗粒更可取,更容易烧结的小颗粒 (< 38μm) 也是如此。 轻微的颗粒不规则性有利于为生坯和棕坯提供机械强度。

Malvern Panalytical 专为粉末注塑成型工艺推出的金属表征解决方案可用于: