Calcium carbonates fulfill a variety of different functions in a wide range of industries:

To provide this range of functionality, calcium carbonates are available in a wide range of different particle sizes, and with different surface coatings. The Mastersizer 3000 laser diffraction system can measure particle size from nanometers to millimeters, with measurements over the range being achieved in only a few minutes. This range and measurement speed enables the particle size of calcium carbonates to be tracked during production processes as well as in quality control of a final product.

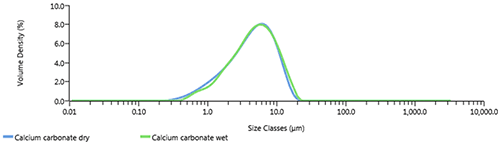

The Mastersizer 3000 has a range of accessories that enable measurements using liquid or dry dispersion. The processing method and particle size of the calcium carbonate will determine whether liquid or dry dispersion is preferable. Dry dispersion allows larger amounts of sample to be measured, providing reproducible results for coarser particle sizes. However, for the finest grades, liquid dispersion offers more control over the state of dispersion, and consequently produces more reproducible results. The flexibility to quickly change between liquid and dry dispersion units means that a wide range of samples types can be analyzed using a single Mastersizer 3000 installation.

The Aero S dry powder disperser uses compressed air to disperse the sample, and the appropriate air pressure must be selected to ensure dispersion [1]. In liquid dispersion, using the Hydro dispersion units, calcium carbonates are usually measured in water. A short duration of ultrasound is often required to disperse agglomerates, and additives, such as sodium pyrophosphate or sodium hexametaphosphate, are used to stabilize the dispersion [2].

Figure 1 shows the particle size distributions for a calcium carbonate sample measured using both liquid (after 1 minute of ultrasound) and dry dispersion (at 1bar). These results show good agreement between liquid and dry dispersion which verifies that that the sample is fully dispersed in both states.

|

Specifying the particle size of calcium carbonates

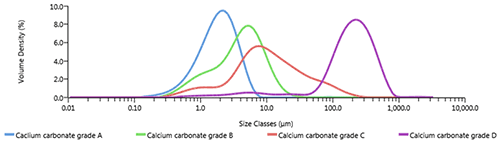

Laser diffraction produces volume based particle size distributions, from which a range of parameters can be specified. For example, the 10th percentile (Dv10) can be used to track the fine particles in the distribution whereas the 90th percentile (Dv90) can be used to track the coarse particles in the distribution. Calcium carbonates are also commonly specified on the percentage material in certain size ranges, for example the percentage below 1μm and 2μm for the finer grades and the percentage above 10μm or 45μm at the coarser end of the range. Figure 2 show the particle size distributions for four grades of calcium carbonate covering a size range from 0.1μm up to 1000μm, and Table 1 shows the parameters for these samples.

|

| Sample | Dv10 (μm) | %V < 1μm | Dv50(μm) | %V < 2μm | Dv90(μm) | %V >10μm | %V > 45μm |

|---|---|---|---|---|---|---|---|

| A | 0.71 | 19.18 | 1.88 | 53.96 | 3.89 | 0.12 | 0 |

| B | 0.95 | 10.75 | 4.15 | 24.35 | 10.2 | 10.47 | 0 |

| C | 1.96 | 5.13 | 9.73 | 10.17 | 55.5 | 49.05 | 12.82 |

| D | 52.6 | 0.79 | 199 | 1.80 | 450 | 93.69 | 90.49 |

Laser diffraction is a widely used technique for the analysis of calcium carbonated due to its wide dynamic range, flexible dispersion options, speed of measurement and reproducibility of results.

[1] Dry powder method development for laser diffraction particle size measurements, MRK1903-01

[2] Wet or liquid dispersion method development for laser diffraction particle size measurements, MRK1902-02