The spraying of liquids is an integral part of fluidized-bed coating and granulation. Examples of products prepared by these processes include detergents, fertilizers, various instant food and beverage formulations and many specialty chemicals and pharmaceutical products.

In the coating process, a spray of fine droplets is generally preferred for even distribution of the liquid onto the mass of the solid particles (or granules), as larger drops may lead to over-wetting and unwanted agglomeration. In the granulation process different sizes of binder droplets provide different conditions of nuclei formation and granule growth and thus may significantly influence the granulation end point. The characterization of liquid sprays is therefore an essential pre-requisite for process optimization and troubleshooting.

The droplet size distribution delivered by the nozzles used in coating processes is dictated by the properties of the coating liquid (density, viscosity, surface tension), the liquid flow rate through the nozzle, the nozzle geometry and, in the case of a twin-fluid nozzle, the flow-rate or pressure of the secondary gas supply. Although order-of-magnitude estimates of the mean droplet size can be made from established correlations, in general the most practical and reliable way to determine droplet size distributions is to measure them experimentally under the conditions of interest for the nozzle of interest. There exists a wide variety of nozzle characterization techniques; these include collection based methods, imaging analysis and techniques using laser light scattering or absorption. Of those available, laser diffraction provides a flexible and rapid approach for the assessment of the delivered droplet size, providing advantages in terms of the ease of set-up and the ability to carry out real-time measurements regarding the evolution of the spray plume.

In this study Malvern Spraytec has been used to measure the droplet size of the spray produced by a lab scale twin-fluid nozzle (Schlick 970S1). This nozzle utilizes the kinetic energy of high-pressure gas (air in this case) to break up the liquid stream into a fine spray. It is used in a desktop fluid bed granulator for the spraying of various binder liquids, including aqueous solutions of polymers. The behavior of the nozzle for different atomization conditions and different liquids has been investigated.

Different spray profiles were characterized by systematically varying the air pressures from 0.25 to 2.0 bar and liquid flow rates from 5 to 20 ml/min in order to determine the droplet size distribution for the operating conditions of interest. The droplet size distributions presented below were measured in the axis of the spray plume, approximately 50 mm from the nozzle exit (it is well known that droplet size variation can occur as a function of position in the spray plume).

The overall atomization performance was determined for operation of the nozzle using de-ionized water and a typical binder used in pharmaceutical granulation, in this case a 5% aqueous solution of polyvinyl pyrrolidone (PVP).

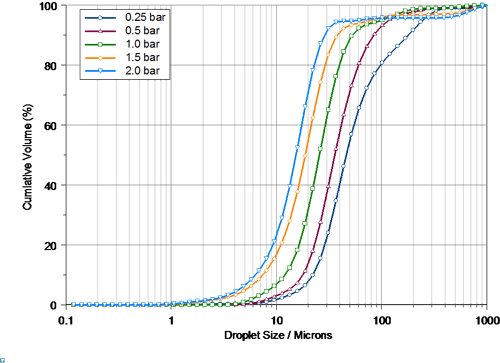

Figure 1 shows the droplet size distributions reported by the Spraytec for the atomization of de-ionized water. The flow rate of de-ionized water through the nozzle was kept constant at 10 ml/min whilst the supplied gas pressure was varied. As the pressure increases the droplet size distribution shifts to smaller droplet sizes. This relates to the increased shear observed within the atomization zone at higher pressures. Even so, the nozzle does produce large droplets, even at high air pressures, as shown in the results obtained at 2 bar pressure.

|

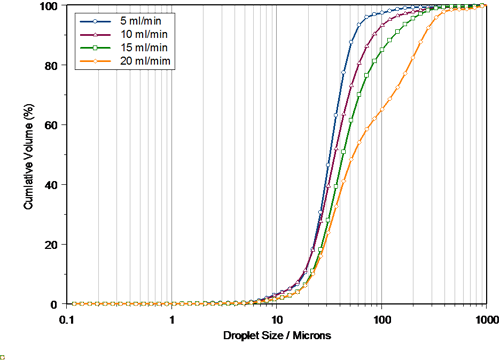

For different processes there may be a requirement to increase the mass flow of liquid through the nozzle in order to reduce coating times or increase coating thickness. Figure 2 shows how the flow rate of de-ionized water through the nozzle affects the spray plume properties at a fixed atomization pressure of 0.5 bar. The size distribution was found to increase in proportion to the liquid flow rate, tracking the change in the available atomization energy per unit volume of liquid.

|

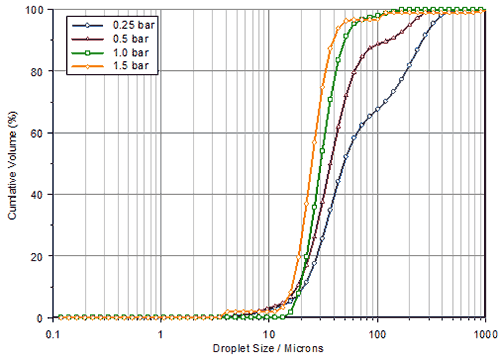

Similar observations were noted when the above experiments were repeated with a 5% PVP solution, at selected gas pressures and liquid flow rates (Figures 3 and 4). In Figure 3, the size distribution observed at 0.25 bar pressure was found to be bimodal. This is probably due to viscous forces in the PVP solution that impart a resistance against droplet formation at lower air pressures. This bimodality progressively disappears as the pressure, and therefore the atomization energy, is increased.

|

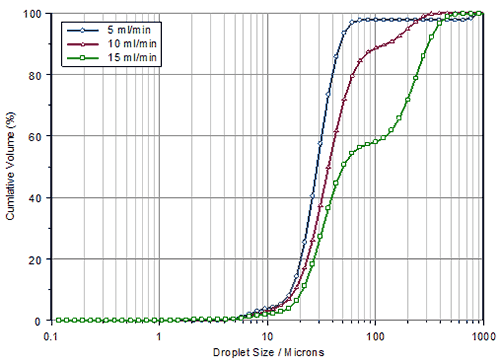

|

The same explanation could describe the bi-modal distribution observed at 15 ml/min in Figure 4. An air pressure of 0.5 bar seems in-adequate to produce a uniform PVP spray. Only when the liquid flow rate is decreased, or the atomization pressure increased, is a uniform size distribution observed.

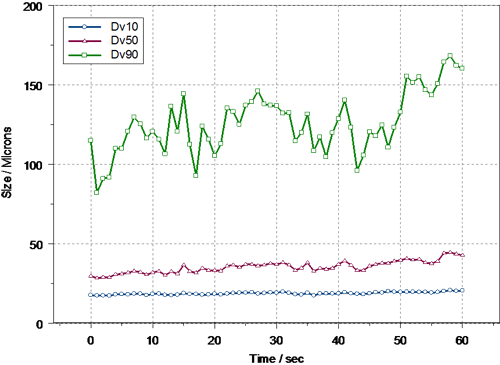

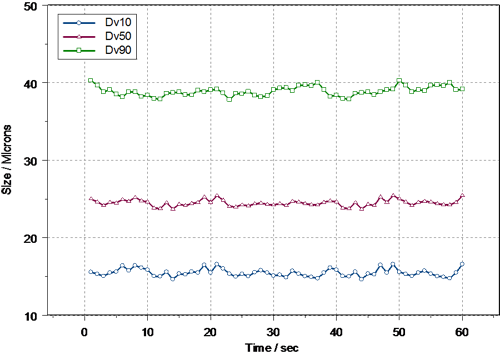

The variable nature of the PVP spray plume observed at low pressures is confirmed by examining the changes in the measured droplet size as a function of time during operation of the atomizer. This is shown in Figure 5 for the atomization of the 5% PVP solution at a pressure of 0.5bar and a flow rate of 10 ml/min. As can be seen, significant changes in the measured Dv90 are observed over time (Coef. Of Variation = 15%), representing significant fluctuations in the coarse droplet fraction. This suggests that liquid break-up is relatively uncontrolled in this situation as the atomization energy available is low. At higher atomization pressures the variation in the Dv90 is considerably less (Coef. Of Variation = 1.5% at 1.5bar for the 5% PVP solution), representing a more uniform spray plume (Figure 6).

|

|

The measurement of the droplet size distribution produced by a twin-fluid spray nozzle has been demonstrated. The results obtained show that the size can be regulated by adjusting gas pressure and liquid flow rate. In addition to these process parameters, the physical properties (e.g., viscosity) of the spraying liquid also play an important role in defining droplet size and its distribution.

The Spraytec system provides a reliable and rapid way for spray characterization. The system is therefore a valuable tool in designing, optimizing and troubleshooting of coating and granulation processes.