Chocolate is without doubt one of the world's best-loved foodstuffs. Fry and Sons produced the first plain chocolate bar in 1847, with the first milk chocolate product being launched by Nestle in 1870's [1]. Initially product consistency was poor. However, the introduction of the chocolate kneading process, referred to as conching, by Lindt in 1879 yielded improved flavor and texture [1]. Since then the world's desire for chocolate products has expanded rapidly such that in 2009 chocolate consumption worldwide reached over 7.2 million metric tons [2].

For the consumer, taste is the overriding factor in selecting a chocolate product; for the producer, consistent high quality using optimized, economical and efficient production systems is vital. While there are many parameters to be considered in the production of chocolate, a major factor at all stages is the solid ingredient particle size distribution as this has a significant effect both on the final product and on the cost and efficiency of the production process itself.

This application note examines why particle size distribution analysis is important in the manufacture of chocolate. Examples of the characterization of different chocolate products using laser diffraction particle sizing are also described.

For many years, chocolate manufacture was regarded as a highly skilled process, heavily dependent on the expertise and experience of those involved at each stage of production. However, given the expanding and competitive market for chocolate, the requirement for mechanization and automation of the production process has increased. This change has required a greater analysis and knowledge of the underlying processes involved in chocolate production. Understanding, monitoring and controlling particle size during the mixing and grinding of the chocolate ingredient, has therefore become important in ensuring product consistency and quality.

Chocolate is a suspension of sugar, cocoa and milk particles in a continuous fat phase. The aim of chocolate production is to give this suspension the optimum flow properties for further processing.

Through the processes of fermentation, drying and roasting, the cocoa bean remains reasonably intact with a particle size of several millimeters. While the subsequent processing may differ depending on the product and manufacturer, there is a common requirement for the particle size of the cocoa solids, sugar and any milk solids to be reduced via grinding. Control of particle size during grinding, conching and subsequent processing is important for a number of reasons. For example, if cocoa and sugar particles within the product are too coarse consumers will describe the mouth-feel as "gritty" and flavor release will be poor. Conversely, if the particle size is too fine the product will require greater amounts of cocoa butter to wet the ingredients and achieve the correct rheological properties, resulting in a mouth-feel that is 'sticky'. This also increases production costs as the energy consumed during grinding is high and cocoa butter is generally the most expensive ingredient.

The traditional technique for particle size estimation during chocolate production involved diluting the chocolate in an appropiate dispersant and then measuring the maximum particle size using a micrometre. Although this provided a means of following grinding, it was subject to operator-to-operator variability and did now allow for an assessment of the entire particle size distribution of the product.

Laser diffraction has now replaced micrometre measurements, providing an effective method for assessing the entire particle size distribution of chocolate products. This provides greater control of grinding operations, improving product consistency as well as enabling better management of production costs. As with micrometre measurements, laser diffraction requires the chocolate to be dispersed in an appropiate liquid, normally Volasil 334 or IsoPropyl Alcohol (IPA), to suspend particles and at the same time dissolve fats and other intermediates. The measurement workflow, from sample dispersion through to particle size measurement, is largely automated, making the technique ideal for routine production and quality control operations. The measurements described below show the application of the technique to detecting differences in the particle size of different chocolate products.

The chocolate products available for resale have different properties dependent upon the country of origin and the target market within each country. As such, there is no standard chocolate recipe and significant differences both in raw ingredients and the particle size distribution can be observed.

Here, the Mastersizer laser diffraction system has been used to characterize different chocolate products. Each measurement was carried out in IPA, with 3 minutes low-power sonication being used to melt and disperse the chocolate prior to measurement.

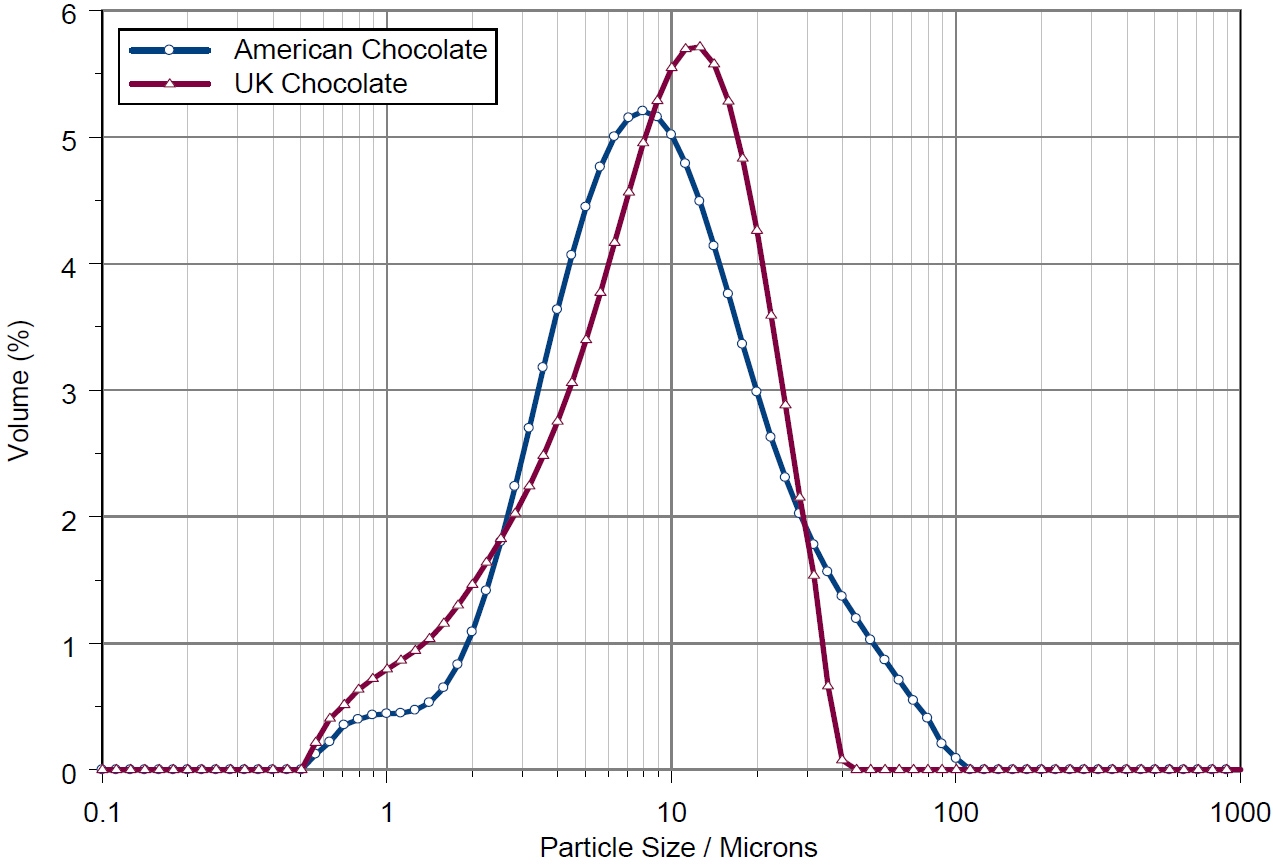

Figure 1 shows a comparison of the particle size of two leading brands, one sold in America and the other in the UK. The requirements for mouth-feel and flavor differ between these two countries, with the UK consumer being used to a smoother mouth-feel. This not only affects the composition of the chocolate but also defines the end particle size. As can be seen in figure 1, the size distribution for the American chocolate extends to much larger particle sizes compared to the UK product. This yields a grittier product with different melting and taste release characteristics compared to the UK product.

Figure 1: Particle size distributions recorded for UK and American chocolate bars.

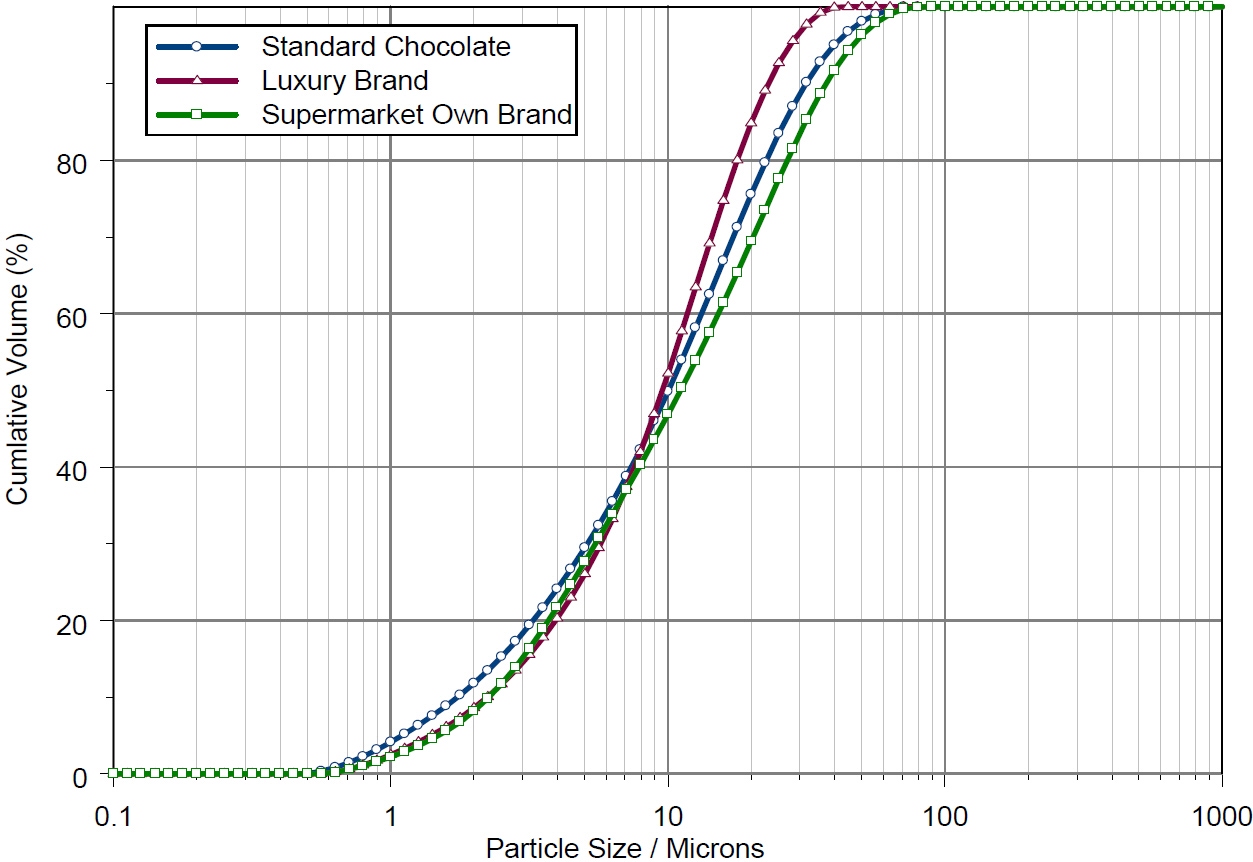

Some brands of chocolate market themselves as providing a luxurious, smooth feel. Again, the required melting characteristics and lack of grittiness are achieved both through the choice of ingredients and through controlling the particle size. This is shown in figure 2 where a so-called luxury brand is compared against a standard brand and an economy brand. As can be seen, the particle size distribution moves to larger particle sizes in moving from the luxury product to the economy product. Obviously the milling and conching duration used for the economy brand will be much shorter. In addition, the amount of expensive cocoa butter required during processing will also be less.

Figure 2: Particle size distributions recorded for Standard, Luxury and economy (Supermarket own) brands.

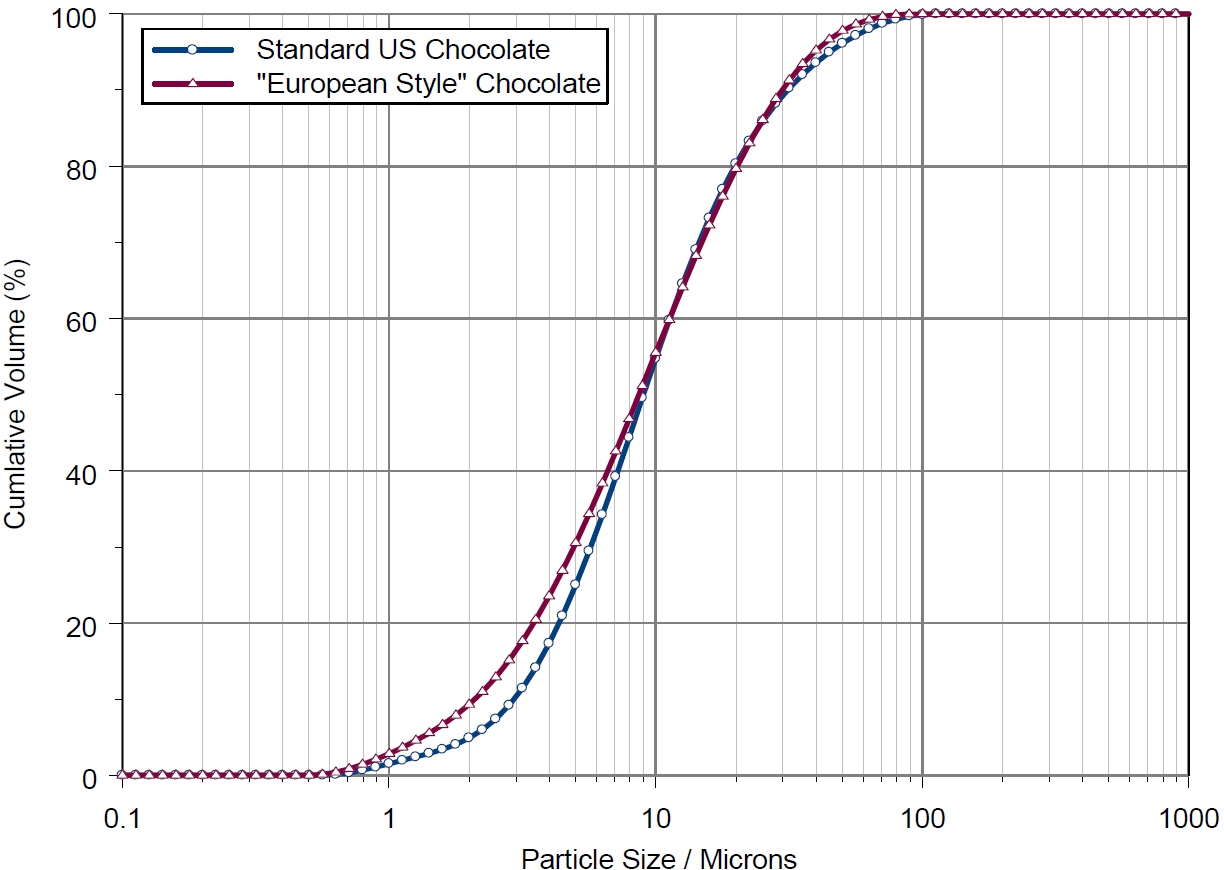

The above example related to the UK market. A similar trend is also observed for the US market. In figure 3 the US brand shown in figure 1 is compared against another product designed to yield a smoother, more-European mouth-feel. Again, in order to achieve this, the ingredients are ground to a finer particle size, although the difference observed is less pronounced than would be expected considering the properties of most UK brands. More noticeable, perhaps, is the change at the fine end of the distribution. This relates to the change in the cocoa and milk solids content required to mimic a European brand.

Figure 3: Comparison of a standard US brand against a chocolate product designed to be more European in taste and texture.

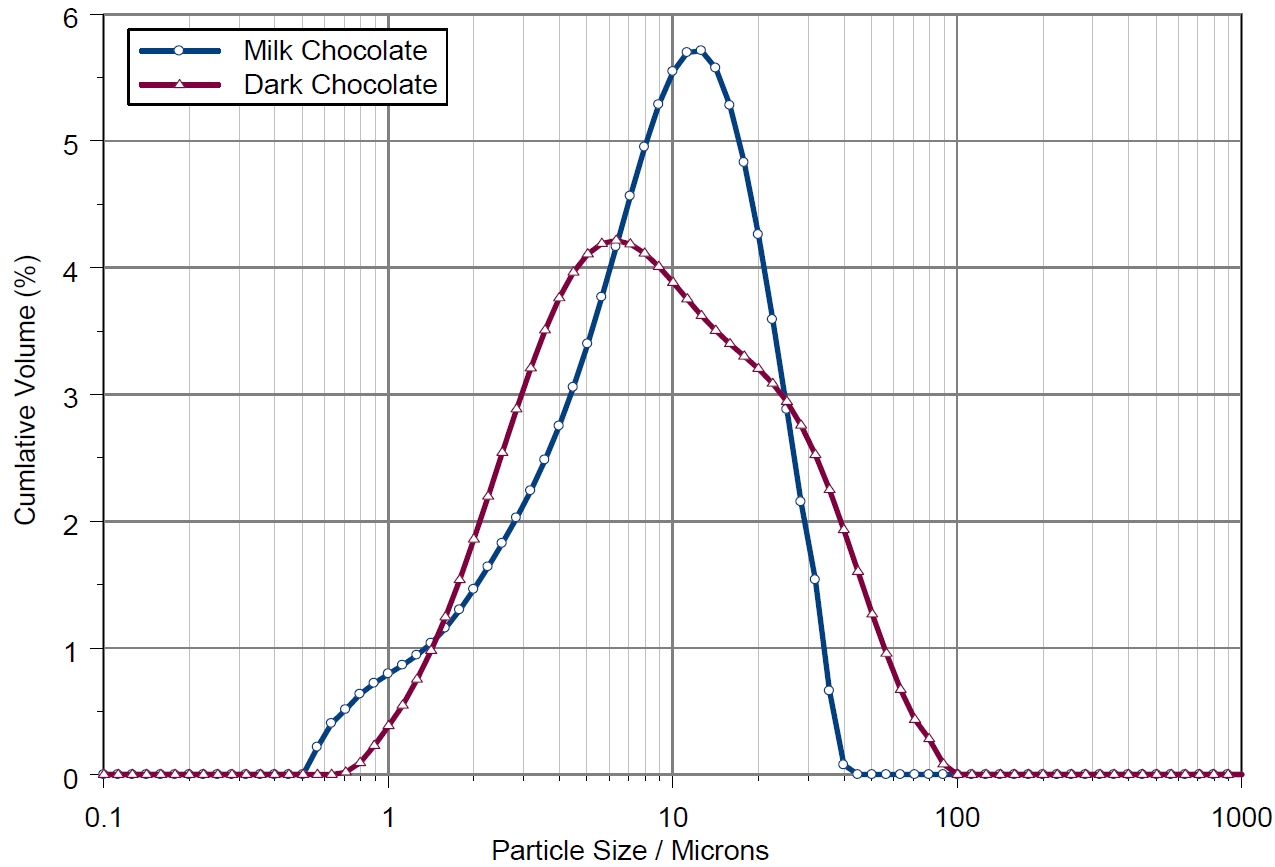

The difference between dark and milk chocolate is shown in figure 4.Here, the differences observed relate to the ingredients used. Dark chocolate generally contains a large amount of sugar in order to produce a palatable product. This yields a coarser particle size and a grittier mouth-feel. Differences are also observed at the fine end of the distribution - these relate to the presence of milk solids within the milk chocolate.

Figure 4: Particle size distributions recorded for milk chocolate and dark chocolate (UK market).

Most people would say they like chocolate, but what they're enjoying could be vastly different in terms of flavor release and mouth-feel. Particle size is an important parameter in defining the properties of the final chocolate product. Its measurement is therefore vital in allowing the desired product properties to be developed in an economic way.

[1] Tannebaum, G., "Chocolate: A Marvelous Natural Product of Chemistry", Journal of Chemical Education, vol 81, no 8 (August 2004), p 1131- 1135

[2] See: http://www.statista.com/statistics/238849/global-chocolate-consumption/ [Accessed July 2015]